Your advantages

- Only one supplier, from the first idea to the prototype to the series production

- Perfect knowledge transfer from prototype to series production

- No loss of quality due to a change of supplier

- Resource-saving development because we identify problems early on in the prototype process

- Knowledge gained from prototype production flows into the series.

Clear task definition

You need a prototype. And then the series for this part. Or only series parts. We can do both – prototype and series. And you only talk to one supplier.

You come to us with an idea or a concrete conception of the future component. We develop the prototype with you. At the latest, you can now focus on your core business again. We manufacture the parts at the required time and in the required quantity. In the end, you receive ready-made components – in series.

The severe disadvantage is if you need two suppliers.

One for the prototype, the other for the series

- You have the prototype manufactured by supplier A

- Because he cannot produce a series, you then go to supplier B, who produces your parts in series.

- The disadvantage: From one supplier to the next, there are losses in terms of quality, knowledge and experience

- The consequence: The series supplier starts from scratch again because he lacks experience in the prototype phase

- Precious time is lost

- Everything becomes more expensive

This approach is cumbersome, time-consuming and error-prone.

The alternative: With one supplier, you save time and money

With one supplier for prototypes and series, you have a seamless transition. No loss of knowledge. No loss of quality. No loss of time

No unnecessary costs. We use a digital twin as early as the prototype development phase to speed things up. This enables us to identify potential problem areas in the series before. This prevents unpleasant surprises in the series – and saves time and costs. Even your purchasing department is pleased because it has only one supplier for prototypes and series.

You have only one contact person for the entire transaction to ensure that the process runs smoothly for you.

You now have the choice in milling.

You decide where to have your milled parts manufactured in the future. You have two options.

They leave everything as it is. For the prototype, you go to supplier A. For the series, you go to supplier B. The serious disadvantage is that the experiences from the prototype phase do not end up with supplier B. He starts over, losing precious time instead of benefiting from Supplier A’s knowledge. Your project is dragging on.

You take the shortcut, work with Wenz Mechanik and benefit from the fact that everything continues seamlessly after the prototype phase because we can do both prototype and series. No loss of quality, no loss of time, no unnecessary costs.

What prospective customers always ask:

Can you also make a prototype?

That is one of our strengths. We ensure rapid implementation, from the idea to the sketch to the finished milled part as a prototype. Especially if you want to obtain this milled part in small or large series, you are at the right place with us because we master both.

What are the maximum dimensions of the machined parts that you can machine during milling?

The maximum size is 800x400x300mm in the cube.

What does your machinery look like?

We have precise 3- and 5-axis Hermle machining centers in single-part production.

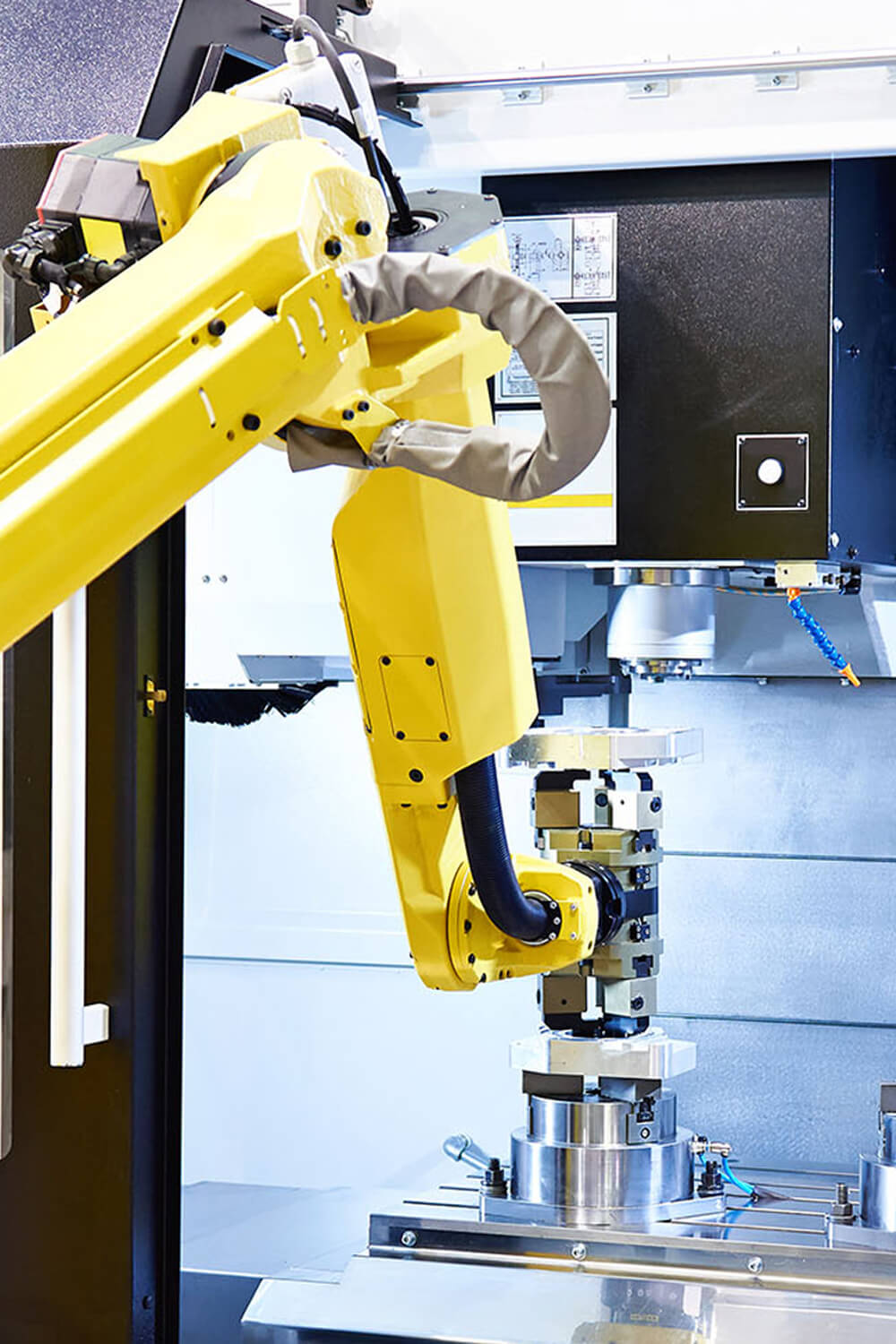

In series production, we work with fully automated Fanuc 5-axis machining centers.

What kind of milling can you do?

Precise 5-axis machining

What do you specialize in when it comes to milling?

We specialize in the milling of functionally critical components made of common metals.

In which industries besides mechanical engineering do you specialize?

Automotive industry and medical technology

Can we have both made by you? Prototype and series?

Yes, we can do both. Produce a prototype. And from it, make the series. You save time and money when we do both for you.